how does a brake line compression fitting work

When placed on a brake line the fitting creates a tightened joint. Click to see full answer.

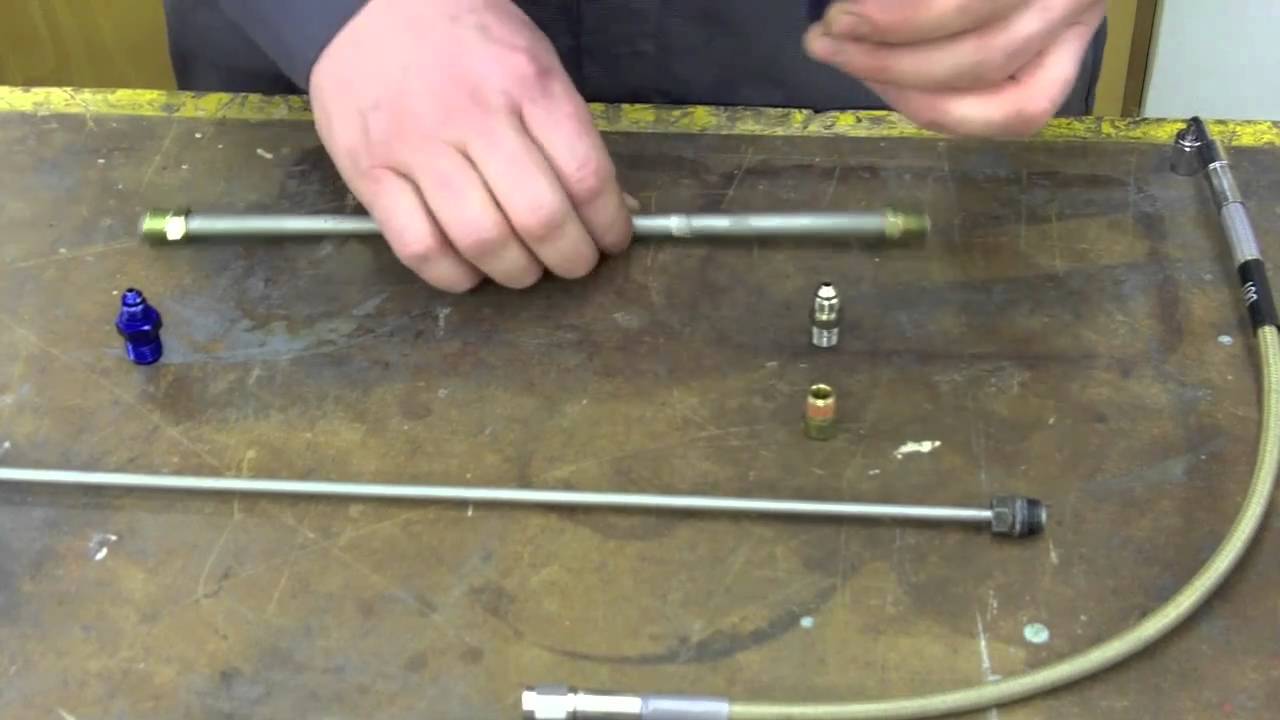

How To Connect Brake Lines With New Fittings A Union Youtube

In particular this accessory usually connects two parts of the brake line and prevents leakage.

. The compression fitting is comprised of a nut and a ferrule. Compression fittings can splice pieces or sections of steel brake line together to create a seal between the two sections. The freaking package says do not use on automotive brake systems.

You cannot under any circumstances use compression fittings to repair the lines on a public transportation vehicle. Ad Buy Compression Fittings from Justrite Get the Perfect Fit for Your Body. The parts store gave me the correct line and a compression fitting to join the new and old sections.

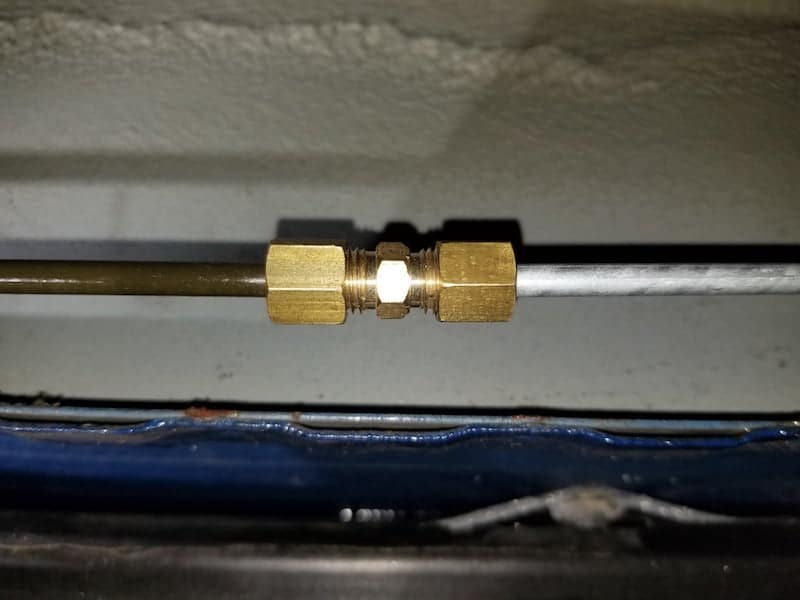

How does a compression fitting works. Compression outlets typically consist of the pipe a nut a compression ring and the fitting itself. When placed on the brake cord the fitting makes a tight connection.

The ring the nut and the seat. Rotate the lapping head back and forth about 6-10 times. Compression fittings typically are not capable of withstanding this high amount of pressure.

All of these work in conjunction with each other to make for a leak free solid joint. Compression fittings work well if the pipe is clean and cut properly. Under a panic stop that can double.

When placed on a brake line the fitting creates a tightened joint. Buy online for free next day delivery or same day pickup at a store near you. This form of repair is common because of the idea that the fitting prevents leakage.

How does compression fitting work. The pressure running through brake lines is extremely high. How to Seal Flare Fitting Connections Unscrew the brake line from the fitting.

In general these fittings are made up of three components. This exerts pressure on the olive and bites it onto the pipe. If the compression fitting is to be blown towards this type of vehicle the low speed will allow the driver to roll slowly until it stops.

The nut and ring are placed on the pipe then the fitting is placed at the pipes end. Your 1 Stop Shop For Safety Cabinets Cans Spill Protection. It is a metal object which connects one component of the coupling to another usually some type of pipe to create a waterproof seal.

Compression fittings typically are not capable of withstanding this high amount of pressure. Compression fittings are used to join two pieces of brake line together. 20 off orders over 120 Free Ground Shipping.

How do you seal brake line fittings. Insufficient tightening of the compression nut will not deform the ferrule enough to create this contact but over-tightening will deform the ferrule too much creating a surface contact. When placed on a brake line the fitting creates a tightened joint.

Spray some lubricant to the lapping head before using it. Furthermore how much pressure can a compression fitting take. As described in the Ferrules section above the optimal seal is created by a line contact between the ferrule and the tubing.

Many states have banned the use of this repair on passenger vehicles too. Compression fittings are used to join two pieces of brake line together. Unfortunately using brake line compression fittings presents multiple problems.

Compression fittings are used to join two pieces of brake line together. Clean and inspect the flare. This form of repair is common because of the idea that the fitting prevents leakage.

Compression fittings work by the compression of an olive between two tapered surfaces and the pipe itself. These parts are attached to each other by first sliding the nut onto the tube or pipe and then connecting the compression ring. Compression fittings are used to join two pieces of brake line together.

The pressure running through brake lines is extremely high. A compression fitting will handle 300-500 psi just fine but a modern brake system can have pressures just in normal stopping of 1200 psi. They are capable of holding up though.

Compression assembly consists of a nut and a sleeve. I went to buy a new line and a union to replace the broken section. Any vehicle that is not driving on public roads and is not driving at high speeds can use compression fittings for brake repairs.

Brake Line Replacement If the entire line is rusted then measure it allowing an extra inch for error caused by bent lines. Soak the fittings in an appropriate penetrant for about 15 to 20 minutes. Although even brass compression fittings are rated for higher pressures than brake lines hold they do not meet the 41 fail rating versus application standard required.

Clamp the appropriate-sized collet around the line. My brake line rusted and was leaking like hell. Compliant Safety Since 1906.

Repeat soaking if necessary. As the nut is tightened against the fitting the brass ring is deformed against the pipe itself creating a. Identify and remove the.

With the introduction of quick-connect style fittings to the water treatment industry the compression fitting was used less frequently but its still a great fitting that can handle high pressure and give you a reliable. This form of repair is common because of the idea that the fitting prevents leakage. A typical car braking system will produce around 1000 psi.

During temporary maintenance compression fittings can also be used to repair brake lines. The compression fitting is comprised of a nut and a ferrule. Can you use compression fittings on brake lines UK.

A COMPRESSION FITTING VALVE Alright so these fittings are composed of 3 parts the valve in this case a sleeve and a retainer nut. How do compression fittings work on brake lines. The compression fitting is comprised of a nut and a ferrule.

We have the best Compression Fitting for the right price. A compression fitting compresses a component of the fitting into another component usually some type of tubing to create a watertight seal between two different lines. Connect it to the Surseat lapping tool.

This does not hold true for compression fittings. Compression fittings can splice pieces or sections of steel brake line together to create a seal between the two sections. Compression fittings are NOT designed to hold the kinds of pressures that are seen in an automotive brake system.

Brass Brake Line Plug 3 16 3 8 24 I Ags Company

How To Fix Leaky Brake Line Fittings

Top 3 Reasons Not To Use Brake Line Compression Fittings Brakeconnect

Confused By Brake Line Fittings Factory Five Racing Forum

Brake Line Compression Fittings Brake Line Repair Compression Fitting

How To Use Compression Fittings

Connecting Brake Lines With A Compression Fitting Youtube

Amazon Com Dorman 800 203 High Pressure Compression Union Rated For 5000 Psi 1 4 In Automotive

Will A Compression Fitting Work On Brake Lines Youtube

Jegs 635827 Nicopp Brake Line Line 3 16 In X 72 In Black Steel Fittings 3 16 Walmart Com

Fitting Your Project Together A Guide To Brake Line Fittings 4lifetimelines

How To Fix Leaky Brake Line Fittings

Brake Line Repair When To Use A Compression Fitting Doityourself Com

Know How Notes Braided Hose End Guide Napa Know How Blog

Bmw E53 X5 Brake Line Failure Common Issue European Auto Repair Tampa Eurospeed Automotive

Top 3 Reasons Not To Use Brake Line Compression Fittings Brakeconnect

Brake Line Compression Fittings Brake Line Repair Compression Fitting

How To Use Brake Line Fuel Line Compression Fittings What They Look Like How To Use Them Youtube